Or How You Can Learn From My Mistakes!

by Craig Gainza

I've conducted the annual condition inspection on my Lancair IV-P for 14 years. For 13 of them, I have been getting away with an oversight while installing the spinner on my Hartzell propeller. This year it finally bit me!

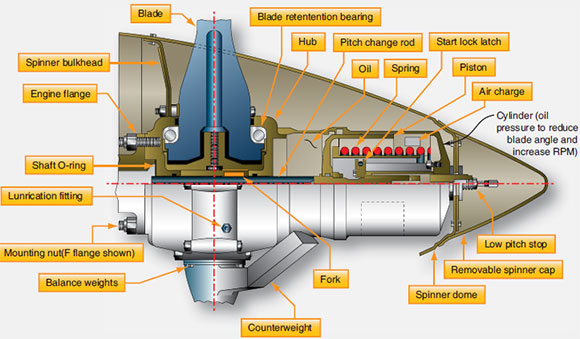

My IV-P has a Hartzell full-feathering, counterweighted, constant-speed propeller, with a two-piece Hartzell spinner. My previous Aerocomposite propeller had a carbon fiber spinner and very simple installation instruction. After changing to the Hartzell, I assumed that spinner installation would be similar.

It is not.

At this year's annual, I attempted to remove the low pitch stop nut, but it would not come off. A closer look revealed damaged threads.

Despite a liberal dose of B'laster lubricant, getting the nut off required enough force to further damage the threads.

After talking with Hartzell and American Propeller in Redding, CA, the error of my ways was made clear: improper spinner installation. I discovered this is a common problem, which prompted me to review the Hartzell manual and share my experience.

After three weeks and excellent service by American Propeller in exchange for lot of money, I received my repaired propeller.

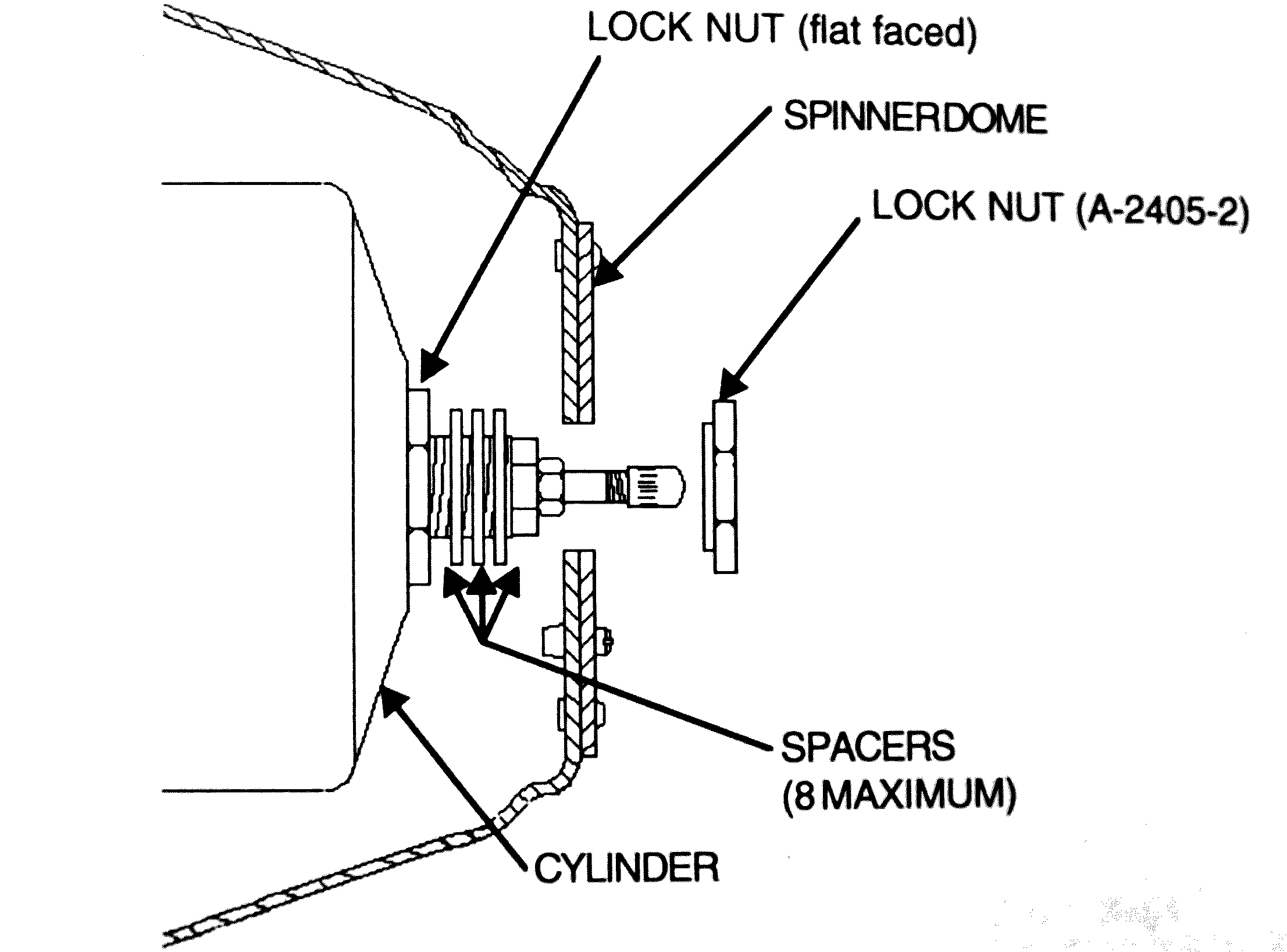

According to the manual, proper installation requires a preload on the spinner to prevent development of a high-frequency vibration, or "buzzing." The vibration, which is unnoticeable to the pilot inflight, can damage the soft aluminum threads on the low pitch stop. Hartzell says this problem is more common on four-cylinder engines, but can sometimes happen with six-cylinder engines like mine. To achieve a preload, the manual calls for spacers between the spinner dome and the low pitch stop lock nut to prevent the spinner from fully seating on the spinner bulkhead.

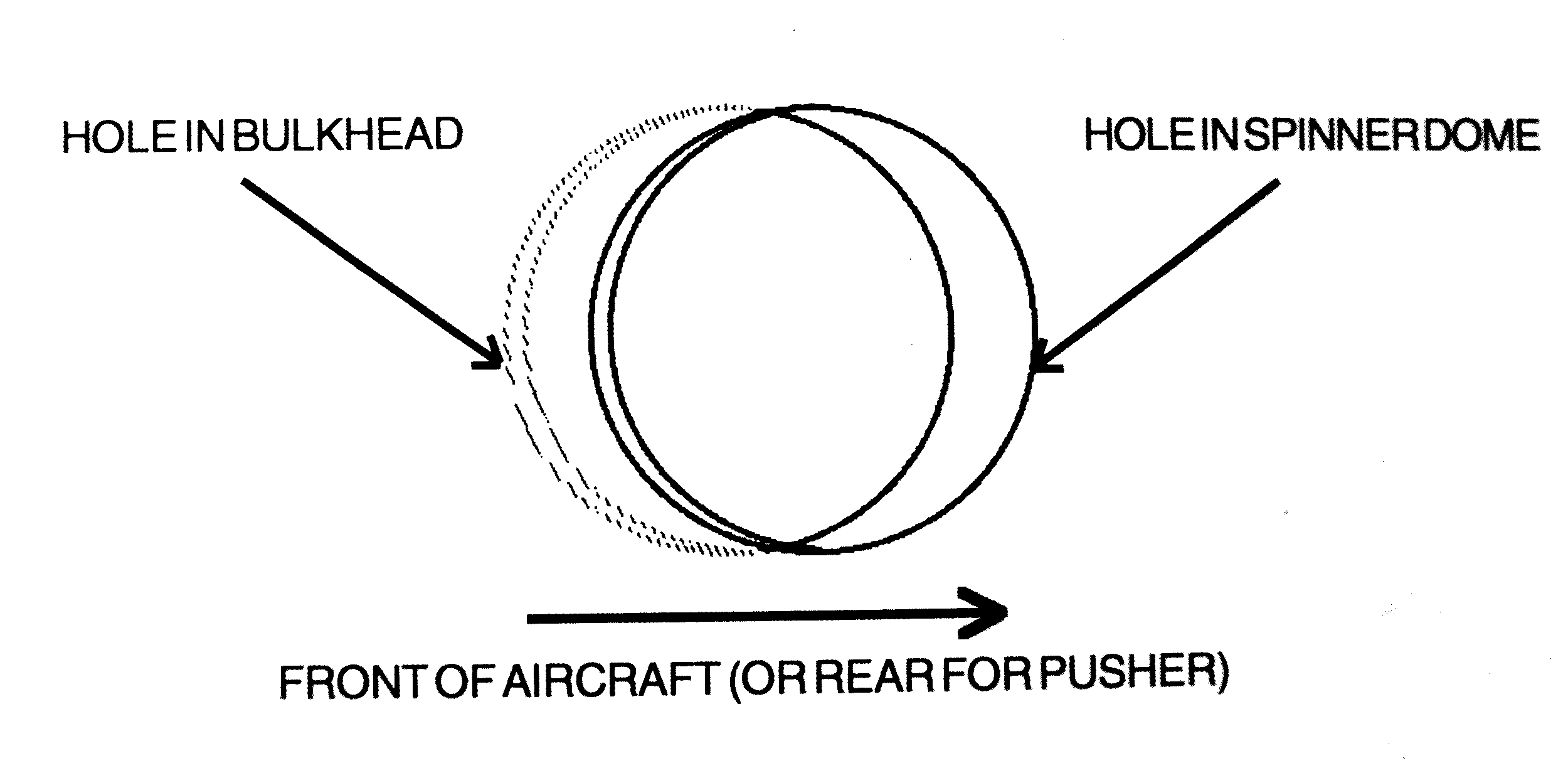

Hartzell recommends adding enough spacers (eight maximum) so that ⅛-¼ inch of bulkhead is visible through the screw holes in the spinner dome.

An awl through the holes in both the spinner dome and bulkhead can help to achieve alignment before inserting the mounting screws. Only after securing the spinner dome with all the screws do you torque and safety wire the low pitch stop nut. It is critical that the low pitch stop nut be precisely torqued to avoid damage to the aluminum threads.

This costly repair and needless increase in down time was easily avoided had I simply followed proper spinner dome installation procedures. I hope by sharing my mistakes I can help you avoid them.

For questions/comments on this post contact LOBO via email: info [at] lancairowners.com.