Valve Failure Could Cause Engine Shut-Down

by bob pastusek

by bob pastusek

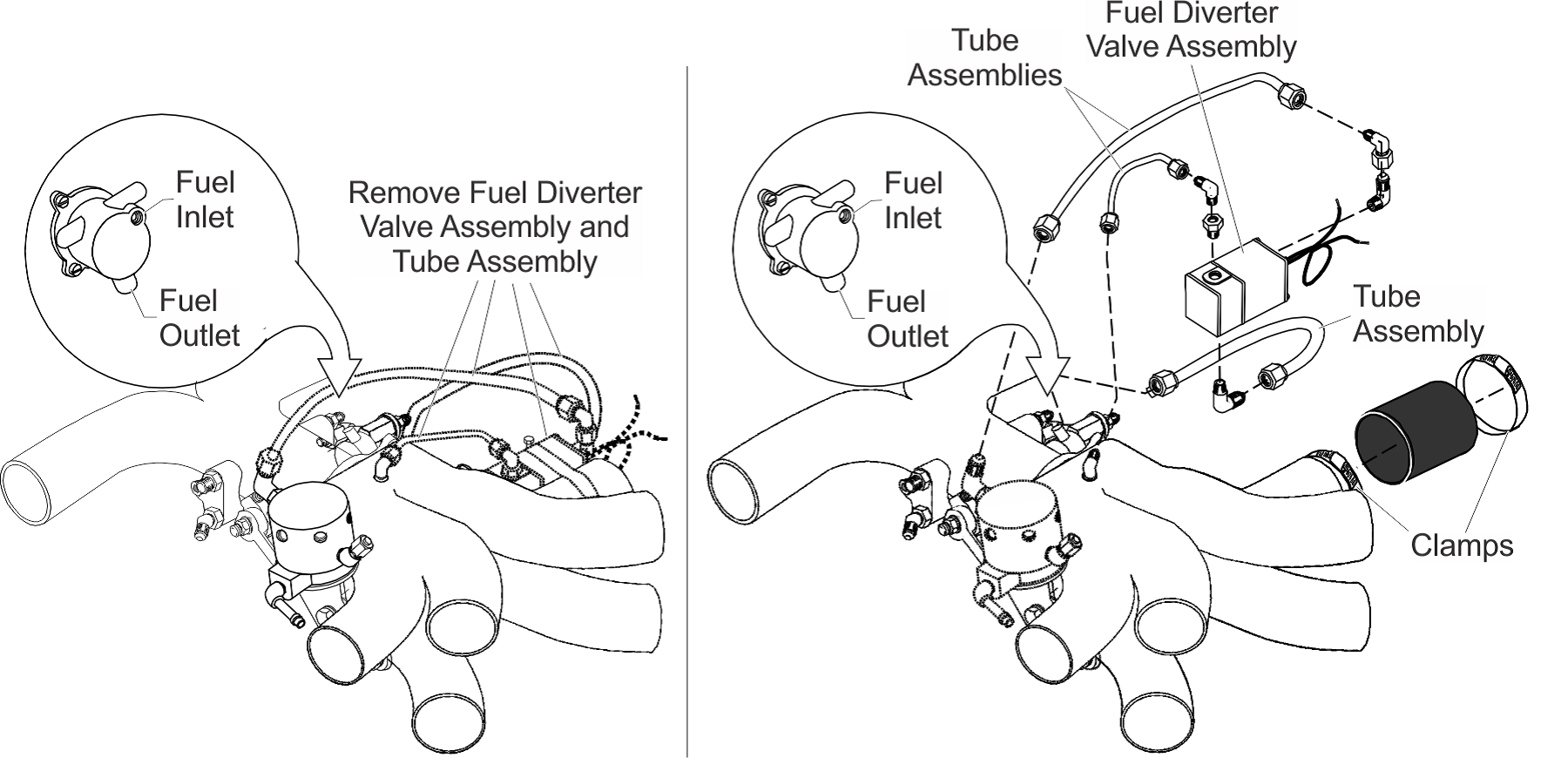

Earlier this year, Continental published a new ![]() Critical Service Bulletin (CSB19-01 Engine Primer Valve Removal) directing the removal of the starting primer valve and associated components from certain models of their fuel-injected 360, 520 and 550-series gasoline engines. This was prompted by several internal valve failures resulting in unintentional engine shut-down. Continental's examination of failed valves discovered a molded-on sealing plug connected to the solenoid plunger shaft can separate and block fuel flow to the engine.

Critical Service Bulletin (CSB19-01 Engine Primer Valve Removal) directing the removal of the starting primer valve and associated components from certain models of their fuel-injected 360, 520 and 550-series gasoline engines. This was prompted by several internal valve failures resulting in unintentional engine shut-down. Continental's examination of failed valves discovered a molded-on sealing plug connected to the solenoid plunger shaft can separate and block fuel flow to the engine.

While compliance with SBs and CSBs is not technically required for experimental aircraft, LOBO has always urged careful review of the issues and intent surrounding manufacturer service bulletins, especially those of the critical variety. Almost always our reviews result in a LOBO recommendation to comply with manufacturer recommendations. This one is a no-brainer.

|

| Fuel Diverter Valve Assembly, TSIO-550-E (from Continental CSB) |

Neal George at Continental says "you ignore it at your considerable personal risk." The up-side is that no expensive parts are required, and the time to accomplish is estimated at less than two hours. It's something you can easily do yourself, and the required parts—a new piece of fuel tubing and a plug for the intake manifold—can be fabricated locally (experimental engines only) or obtained directly from Continental for those who wish to maintain engine certification. Continental feels so strongly about the need to accomplish this CSB that they will no longer sell new/replacement primer valves, and no longer include this primer system as an option on their new engines.

The needed part numbers are shown for different engine models in Continental’s bulletin. If you choose to make the new fuel line yourself be sure to use 3/8" stainless tubing vice aluminum, and make quality tubing flares on each end. This is a critical part in a high-vibration environment.

|

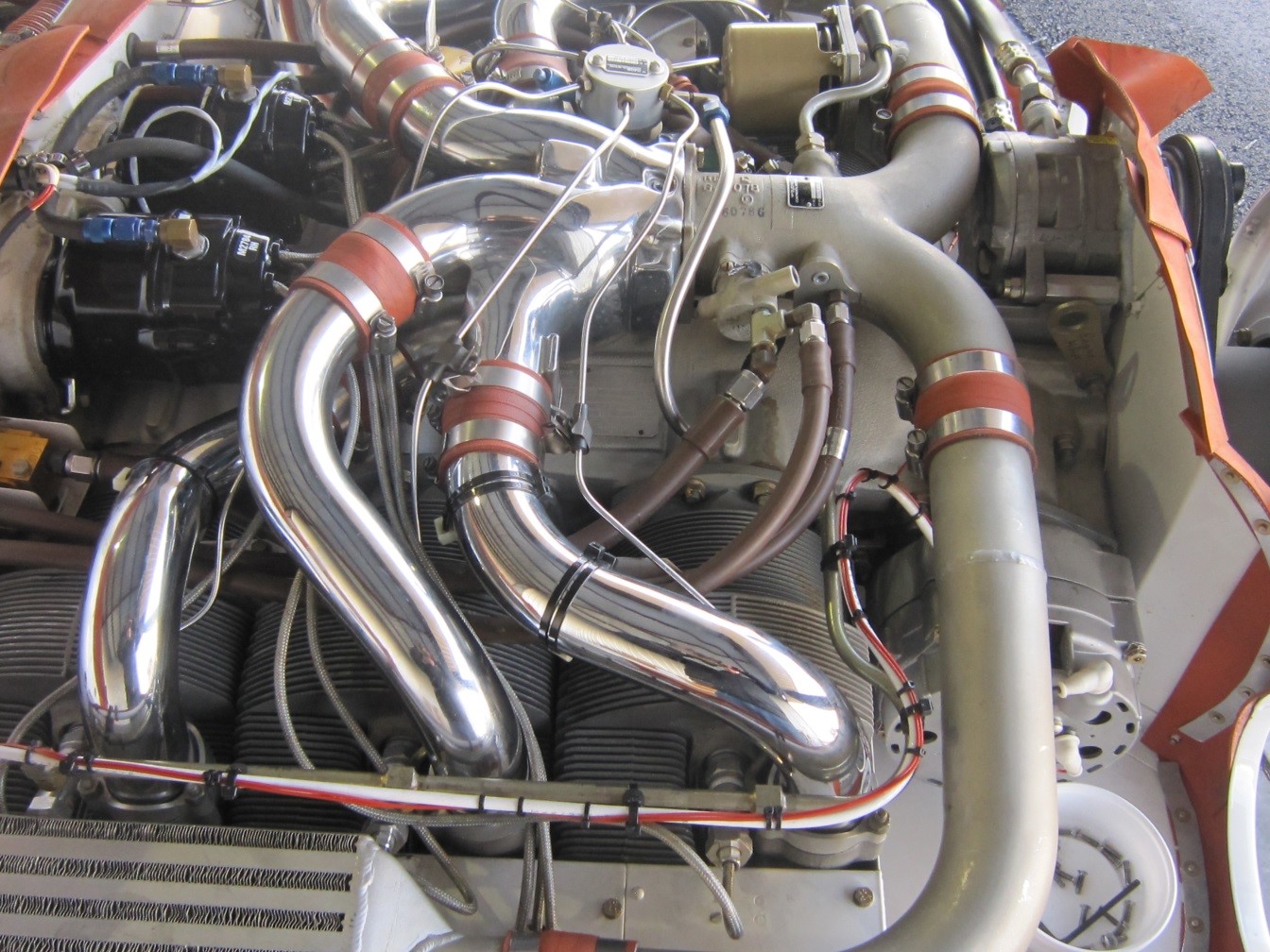

| TSIO-550E with primer valve removed and stainless line direct from metering valve to injector spider. |

Procedural Changes

Engine start is functionally the same, with or without the primer valve installed. For engines equipped with a primer valve, pushing the cockpit PRIMER button activates the aircraft electric boost pump and diverts the main fuel supply to the primer nozzle(s) within the primer valve. With the primer valve removed, pushing the PRIMER button will still activate the electric boost pump, but fuel enters the cylinders through the normal injector system. The amount of priming required to achieve a smooth start may change slightly, but there is no other operational difference. This engine modification gives owners the option to eliminate the PRIMER button entirely and use the electric boost pump switch to prime the engine—as those of us operating Continental engines without primer valves have done for years.

Engine Logs

Whether you do this work yourself or have it done by someone else, be sure to annotate the work in the engine log book. Failure to document maintenance work (repairs or preventive) on experimental aircraft has become commonplace, even though the regs require it. LOBO has noted this even for some highly recommended shops catering to Lancair owners. Note that for experimental aircraft you can make maintenance and repair entries yourself, whether or not you have an A&P or IA license, as can any other person you are likely to allow to work on your Lancair. If you have work done by a shop you should insist in advance on a log book entry by the technician accomplishing the work.

A Note of Caution

With or without a primer valve, there are a couple of cautions/warnings about priming the engine for start. It is possible to over-prime the engine and dump enough liquid gasoline into the cylinders to cause a hydrostatic lock, or hydrolock. This occurs when a cylinder contains enough non-compressible liquid to mechanically prevent the piston from reaching the top of its compression stroke. This can result in a bent connecting rod—or worse—if you are using the starter. If you suspect over-priming, before doing anything else GROUND THE MAGNETOS! Then pull the prop through at least three revolutions by hand BEFORE trying the starter. The best way to avoid hydrolock is to thoroughly inspect the cylinder drains and sniffle valve during each condition inspection. These components allow excess fuel to drain from the cylinders, but they can become blocked with soot/carbon. during normal operation. If that happens fuel cannot drain properly, which greatly increases the likelihood of hydrolock from over-priming.

For questions/comments on this post contact Bob via email: r.pastusek [at] lancairowners.com.